Our Favourite Products

Rated ‘Excellent’

TW WHOLESALE LTD, BUILDERS MERCHANT IN DERBYSHIRE

TW Wholesale LTD is a 3rd generation family business. We supply trade and DIY customers across the UK with power tools, hand tools and all associated products from our superstore and warehouse in Swadlincote, Derbyshire

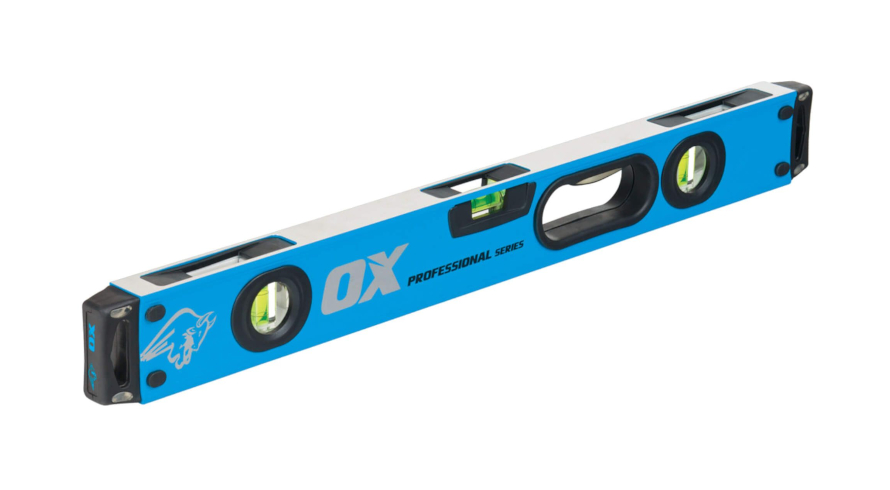

TW is an official stockist for leading power tool brands including Bosch, DeWalt, Makita and Milwaukee. The store also has an impressive stocked range from hand tool manufacturers Stanley, NELA, Refina, Marshalltown, Teng, Ox Tools and many more!

Learn More